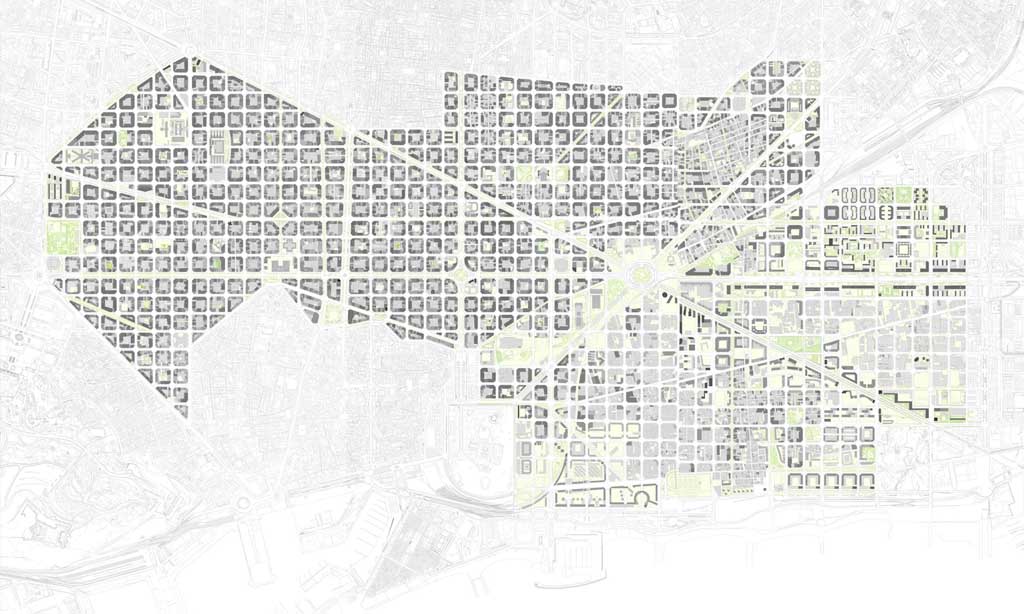

| Summary | In recent years, the first off-shore wind farms have been located in relatively shallow water depths. In these systems, the wind turbines are fixed to the ocean floor, for example by driving monopoles into the sea-bed or by relying on conventional gravity bases. As these parks start to become more common, research is underway to develop "floating platforms" attached to the seabed by mooring lines. This solution will permit the wind farms to be placed in much deeper waters where the wind resource tends to be better.

Research projects, such as "Hywind", "Windfloat" and "IRPwind" are underway to develop floating platforms aimed at developing and demonstrating three main types of floating wind platforms: "ballast stabilized" using spar buoy platforms with catenary mooring drag-enabled anchors; "Tension Leg Platforms" or "Mooring Line Stabilized Platforms" attached to the seabed with suction pile anchors; "Buoyancy Stabilized" platforms employing a "barge" type device with catenary mooring lines. Hybrid concepts, e.g. tension leg buoy (TLB) or semi-submersibles, using a combination of the aforementioned stabilizing forms, are also a viable option currently considered by industry.

Currently, these prototype concepts, when compared to conventional fixed bottom offshore platforms, are much more expensive, with platform cost and mooring systems (especially for tension leg concepts) being the greatest cost drivers. Crucial to the future economic success and thus to the ability to exploit the great resources along coastlines with deep water, floating platforms need to become more cost effective. The aim of this project is to analyze the market to identify alternative cost-effective materials that could be employed in floating platforms in order to obtain cost reductions. This analysis leading to pre-design of a new floating platform, which will also take into consideration the whole process from construction to installation of the floating platform as these issues are also always critical to final installed cost. New concepts combined with new materials might offer a breakthrough in floating platform cost. The vast majority of the projects underway use steel for the construction of the floating platform, although some use concrete for ballast such as Hywind.

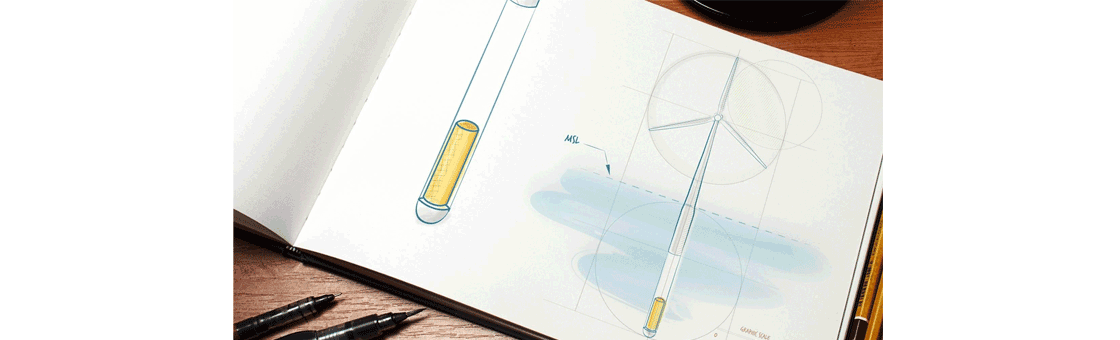

This proposal intends to design and model possible new floating platforms based on alternative materials that should offer the potential to reduce costs. The cost reduction could be achieved e.g. by applying less costly materials than steel, using higher strength materials to reduce weight, or using materials with higher expected reliability to reduce lifetime O&M costs. Amongst the candidate materials to be considered there will be conventional concrete in a tethered buoy spar type design. As stated previously, the construction process will be analyzed throughout the whole process and subsequently defined since it is considered crucial to reduce the costs. In addition, it is expected to develop a system with passive members (which do not require active control) in order to reduce or almost eliminate maintenance costs of the tower and of the anchoring system. Reducing O&M costs is considered as a key issue by many experts.

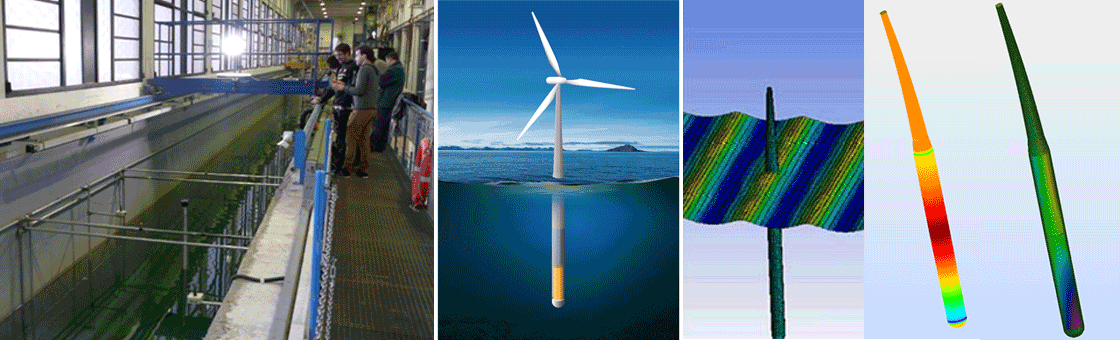

Overall, the AFOSP project main goal is to design and construct a scale prototype of floating platform that will be verified in laboratory, subject to wind loads and in hydrodynamic tests to provide a proof-of-concept design.

More information is available at: http://www.windcrete.com |